THE FUTURE IS

AUTOMATION

A PROVEN PATH TO

AUTOMATION

Control Your Variables

Prepare for automation in your finishing operation by first eliminating variables such as temperature and humidity. Instead of compresses air, patented Nitrotherm and Polifluid technologies use nitrogen for better control and a more consistent finish. All while saving you up to 30% on your finishing system.

Control Your Future

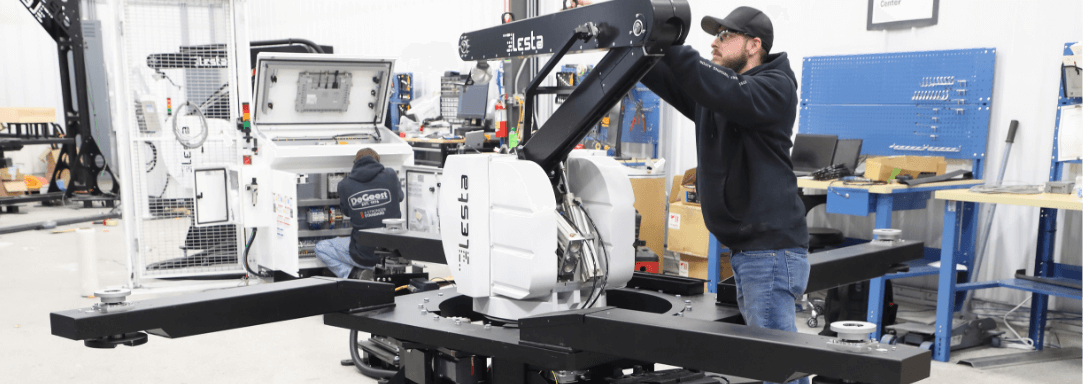

As a leading integrator, DeGeest gets manufacturers robot-ready by capturing knowledge and creating processes to make the transition to automation more seamless. Count on us to put the most advanced robotics and automation technology to work for you along with full integration services.

USING OUR OWN EXPERIENCE, WE’LL ADVISE YOU ON BUILDING A SYSTEM OF YOUR OWN.

Automation

Moving to automation is easier than you think. All it takes is the right roadmap.

You've probably considered automation bu find it overwhelming. No matter where you are in the process, we'll meet you there and guide you to the finish line with a proven blueprint.

The sooner you start, the sooner you'll be able to capture the knowledge of your finishing team while adding technology in phases to help your people and improve your processes.

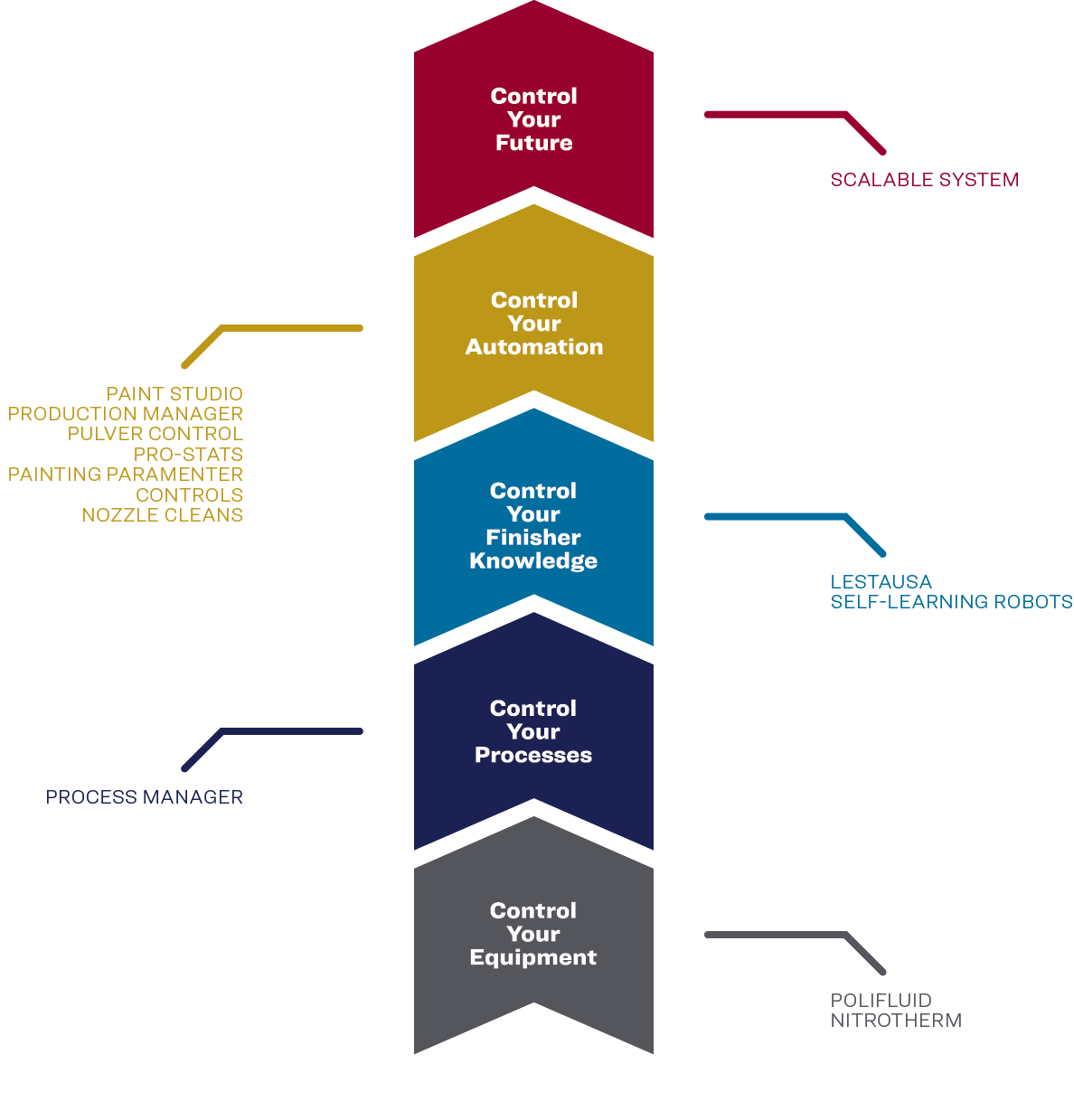

Control Your Future

Have reliable production running on the processes and technology you built into your system. Now, your team can focus on

improvements rather than daily tasks. New employees can be successful with minimal supervision or training. And, you can

depend on your system to scale with you now and into the future.

Control Your Automation

Optimize your finishing robots, automatic reciprocators, and flatlines for increased quality, productivity and team engagement. We have the tools to show you how to adjust programs for day-to-day production, know the current flow rate of materials at each gun, understand your robot’s gun-on time, and learn how many parts your system can produce to hit full capacity.

Control Your Finisher Knowledge

Replicate the experienced decisions made by your painter in real-time. Robot programs are made while your painter is finishing your parts recording all of the ways they adapt to your system’s unique equipment set up, coatings, booth flow, part geometry, with optimal angles, distance to the part, and finishing speed. All of your painter’s knowledge is saved. Automate more than just the path.

Control Your Processes

Document steps in your process to make accurate instructions accessible to pave the way for future automation. How to consistently hang parts, correct masking, quality checks at various stages, proper assembly after paint - we’ll help you control these variables and more with Process Manager, digital work instructions that automate the experience for your paint prep team.

The Sooner you start, the sooner you can Add Automation.

with Brad Ruppert